Founded in 1990, EUWELD® is the global specialist in alloyed cored welding wires. Each of our DRILL-SHIELD hardbanding wires is specifically formulated and produced in-house utilizing our own manufacturing technology and from extensive Oil & Gas industry knowledge.

DRILL-SHIELD® the ultimate protection for your drill string and casing.

DRILL-SHIELD Non Mag sets the standard in joint protection for non-magnetic drill collars and tools. The ultra-low magnetism and permeability of the hardband exceeds the requirements set forth by the API. It is formulated for both buildup and / or hardbanding. During hardbanding it is recommended to use a non-magnetic tungsten carbide drop for ultimate protection.

It is designed for the protection of standard austenitic stainless steels, chromium-manganese, and nitrogen-bearing austenitic stainless steels. It may be applied over defect free laser clad, PTA (plasma transferred arc), or other traditional non magnetic hardbanding wires.

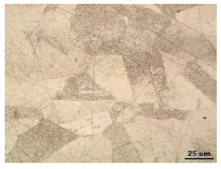

Non-magnetic austenitic deposit

Metal-cored = Increased productivity

Non-cracking, spalling, chipping, or flaking Corrosion resistant

Good ductility

Highest grade alloying elements

Industry leading manufacturing and quality control

Welding Parameters:

| Wire diameter | 1/16″ (1.6 mm) |

| Current / Polarity | DCEP / Reverse |

| Shielding Gas(s) | 98% Ar – 2% O2 |

| Gas Flow: Rate | 35 CFH (16.5 LPM) |

| Welding Amps | 260 to 300 amps |

| Welding Voltage | 26 to 29 volts |

| Wire Stickout “S” | 0.75″ to 1.20″ (19mm to 30mm), from contact tip |

| Torch Angle “A” | 0 deg. to 15 deg. |

| Torch Offset “O” | 0.0″ to 1.25″ (0 mm to 32 mm), depends on O.D. |

| Preheat | 100oF to 150oF (38oC to 66oC) |

| Interpass Temp | Maximum 500oF (260oC) |

| Cooling Rate | Air Cool |

* Circulate water through the I.D. to disperse the heat *